Two years ago, Clemson University principal investigator, Dr. Delphine Dean, figured out a way to make teaching a novel technique in her lab 75% more efficient. Instead of giving her students a text protocol, she published and provided them with a video protocol. The time it took to learn the procedure dropped from 1 month to 1 week. And the video would soon make her the author of the 2nd most-viewed video in JoVE.

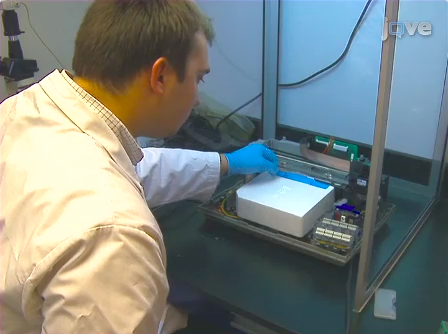

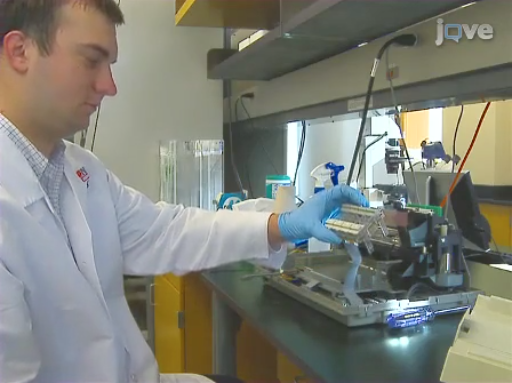

Dr. Dean had originally collaborated on the method with a colleague of hers, Dr. Thomas Boland, in 2010. Their technique—converting an inkjet printer into a bioprinter which could process and print live cells onto microscope slides—proved to be harder for her own lab to adopt than she had anticipated. And so in 2012, Dr. Dean published “Transient Cell Membrane Pores Using a Standard Inkjet Printer” in JoVE’s signature video article format.

In short, using the JoVE video has allowed Dr. Dean’s students to spend less time trying to replicate the procedure and more time applying it.

“We’re in the process of filing a patent for a hacked-up inkjet printer that can [print] diabetic testing supplies for developing countries,” says Dr. Dean speaking of a recent achievement to come out of her lab, “So not putting cells in the ink cartridge, but using enzymes.”

With the help of the JoVE video, Dr. Dean’s students designed the enzyme-printer in under a year. In 2013, those students placed 2nd at the Engineering World Health design competition. Their printer could produce diabetic testing strips (glucometers) for about a penny each, while traditional methods cost about a dollar.

Dr. Dean’s students weren’t the only ones benefitting from JoVE. In 2013, Dr. Dean won a National Science Foundation CAREER award grant using her video. “[It was] kind of an integral part of the proposal in terms of what I’m going to do. I think for that grant in particular [it] was very helpful,” she said.