Fascinated by 3D printing? In this Editor’s Picks collection, Eric Veien, Ph.D., a science editor for our Bioengineering section, discusses four novel experimental techniques in 3D & 2D bioprinting technology.

Dr. Veien: The use of “printing” techniques for biological applications has been increasing in recent years, and is seen as having wide applicability and great potential in bioengineering. Various techniques can be used to print biological substrates, print live cells onto substrates, and to print 3-D scaffolds or entire organs that can be implanted inside living organisms. Interested in learning—seeing—a bit more about this emerging technology? Below are some examples of printing techniques that have been published in JoVE.

Enjoy!

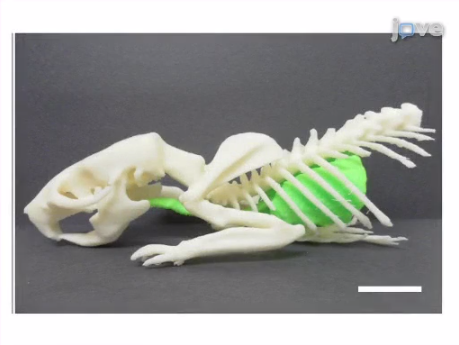

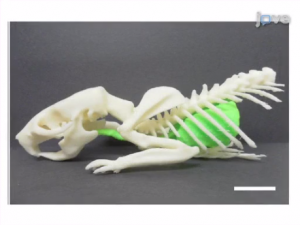

Pick #1: “3D Printing of Preclinical X-ray Computed Tomographic Data Sets”

Dr. Veien: 3D printing can be used to model data acquired by in vivo imaging devices. These authors use an X-ray CT scanner to generate data sets of both skeletal and soft tissue structures from living rats. They then transfer the data to a 3D printer that expels plastic ink to generate exact three-dimensional replicas of these structures, which can be used to more clearly visualize internal structures for use by both researchers and educators.

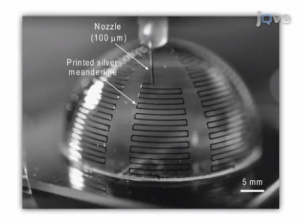

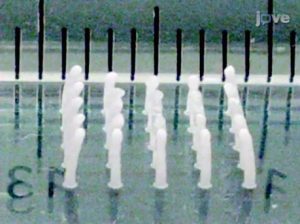

Pick #2: “Planar and Three-Dimensional Printing of Conductive Inks”

Dr. Veien: Here, a 3D printer expels a concentrated ink composed of silver nanoparticles to produce both planar (2D) and 3D structures. The authors used this technique to produce electronic devices such as conductive grids and tiny antennas with both 2D and 3D electronic wiring. However, by using biocompatible protein or hydrogel inks, 3D scaffolds and other tissue-engineered devices can be made using the same basic techniques.

Dr. Veien: In this article, the authors use 3D printing to produce a “sacrificial mold,”—used to form complex structures from materials that can’t be printed. The ink used here is called poloxamer 407, which is unique in that it is a solid gel at room temperature, but liquid at ice-cold temperatures. The mold is printed and then filled with a bio-scaffold hydrogel material such as agarose. The mold is then washed away in ice water, leaving a structured hydrogel that can be used in biological applications such as in cartilage and bone repair.

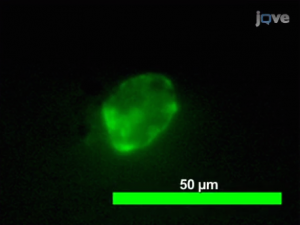

Pick #4: “Creating Transient Cell Membrane Pores Using a Standard Inkjet Printer”

Dr. Veien: This article describes how a standard inkjet printer can be modified to print a suspension of live cells onto a glass coverslip. The printing process temporarily disrupts the cell membrane, producing pores through which molecules, such as fluorescently-labeled proteins, can pass into the cytoplasm. One application of this technique is to label cells so that they can be later tracked in vivo, but it could also be used to print patterned cellular microenvironments or to print cells directly onto biocompatible scaffolds.

Love bioengineering? Check out our other bioengineering methods videos by clicking the image below.