/

/

Fabrication and Characterization of a Conformal Skin-like Electronic System for Quantitative, Cutaneous Wound Management

A subscription to JoVE is required to view this content. Sign in or start your free trial.

JoVE Journal

Bioengineering

Fabrication and Characterization of a Conformal Skin-like Electronic System for Quantitative, Cutaneous Wound Management

Chapters

- 00:05Title

- 01:38Preparing the Carrier Substrate

- 02:20Patterning the Electronics

- 04:32Transferring the Electronics to a Silicone

- 06:14Assembling the Device

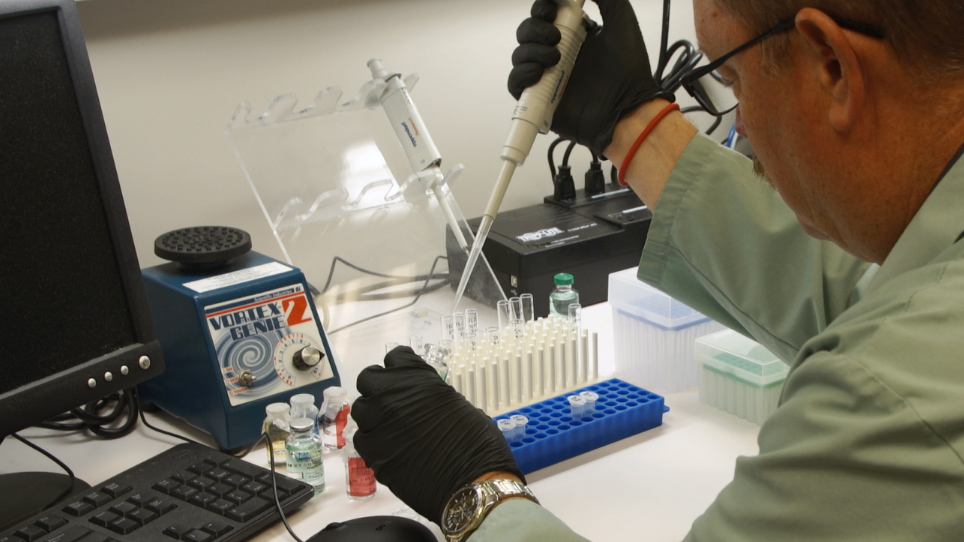

- 07:22Characterization of the Device and Clinical Application

- 08:19Conclusion

This article presents methods to fabricate and characterize a conformal, skin-like electronic system and protocols for the use in clinical applications, particularly on cutaneous wound management.