/

/

Fabricação e caracterização de andaimes de fibra Griffithsin-modificado para a prevenção de doenças sexualmente transmissíveis

A subscription to JoVE is required to view this content. Sign in or start your free trial.

JoVE Journal

Bioengineering

Fabrication and Characterization of Griffithsin-modified Fiber Scaffolds for Prevention of Sexually Transmitted Infections

1Department of Chemistry,University of Louisville, 2Department of Pharmacology and Toxicology,University of Louisville, 3Center for Predictive Medicine,University of Louisville, 4Department of Microbiology and Immunology,University of Louisville, 5Department of Bioengineering,University of Louisville

Chapters

- 00:05Title

- 01:08Preparation and Fabrication of the Electrospun Fiber Scaffold

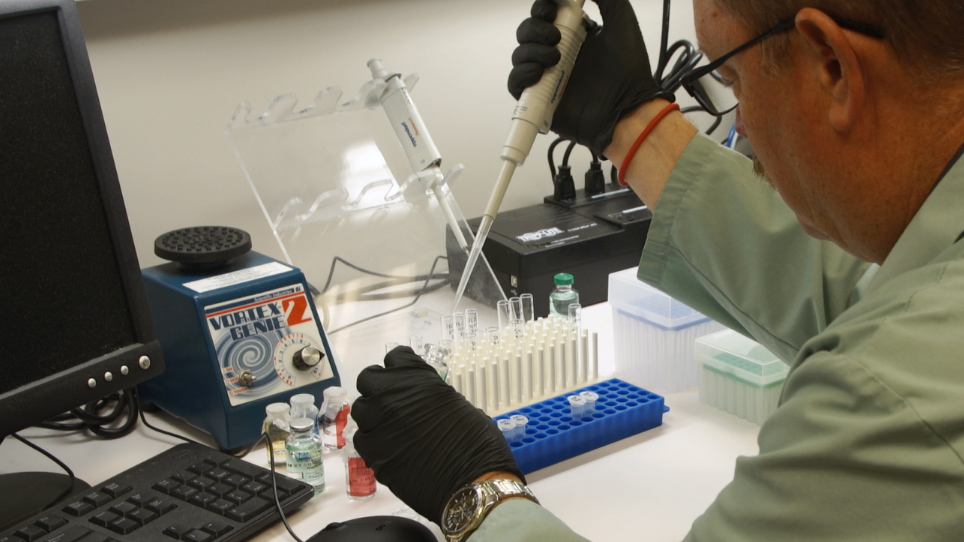

- 03:22Surface-modification of Fibers with GRFT

- 06:35Extraction of GRFT from Surface-modified Fibers and Measuring GRFT Desorption from Fibers

- 08:28Results: Characterization of Griffithsin-modified Fiber Scaffolds

- 10:56Conclusion

Este manuscrito descreve o procedimento para fabricar e caracterizar as fibras de electrospun de Griffithsin-modificado poli (ácido lático-co-glicólico) que demonstram potente atividade antiviral e adesiva contra infecção por vírus da imunodeficiência humana tipo 1 em vitro. Métodos utilizados para sintetizar, modificar a superfície e caracterizar a morfologia resultante, conjugação, e dessorção de Griffithsin superfície-modificado com fibras são descritos.